We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for electric mining truck. How about to start your good business with our company? We are ready, trained and fulfilled with pride. The product will supply to all over the world, such as Macedonia ,Mongolia ,Jersey ,Hong Kong ,Serbia . With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. We keep long term business relationships with wholesaler and distributors form more than 50 countries.We would like to establish good business relationships as well as friendship with you in the near future. We have an available stock of spare parts in our warehouse. This allows us to achieve the fastest electric mining truck delivery times in the shortest possible time. In addition, standard spare parts reduce the procurement of spare parts for the end user.

electric haul trucks

electric haul trucks also named Electric Off-Highway Mining Truck. the trucks transport 60 tonnes or more of rated limestone and marl to the mining areas at low altitudes by means of a fixed-mounted transport system. the trucks are equipped with a battery that can be used for driving uphill with no load. The energy stored in the batteries is used for driving uphill unladen, while the remaining energy is fed into the grid. More power is generated downhill than is needed to return to the top because of the greater weight.

How electric haul trucks compare to diesel trucks in terms of performance

electric haul trucks demonstrate significant improvements and advantages over diesel trucks in several key performance areas:

- Power and torque: electric motors provide instantaneous torque, enabling electric haul trucks to accelerate faster and handle steeper grades more efficiently than diesel trucks. For example, Caterpillar's electric dump trucks can climb a 10% grade at a steady 7.5 mph with a full load

- Speed and load capacity: electric haul trucks can reach comparable or even better speeds when carrying heavy loads. The Caterpillar 793 electric truck can reach a top speed of nearly 40 mph with a 240-ton load, similar to a diesel truck.

- Efficiency: Electric haul trucks typically use regenerative braking, which converts kinetic energy back into stored electrical energy, improving overall efficiency. This feature is particularly useful in mining operations where stopping and dropping is frequent.

- Maintenance and operating costs: electric haul trucks have fewer moving parts than diesel trucks, resulting in lower maintenance costs and less downtime. Lower fuel costs also contribute to significant operating cost savings over the life of the truck.

- Environmental impact: electric haul trucks produce no emissions when in use, thus significantly reducing the carbon footprint of mining operations. This benefit is in line with the industry's growing commitment to sustainability and regulatory compliance.

- Reduced noise: electric haul trucks run much quieter than diesel trucks, reducing noise pollution and creating a safer and more comfortable working environment for operators and neighbouring communities.

While electric haul trucks offer significant benefits, there are still challenges, such as the need for extensive charging infrastructure and the limitations of current battery technology. However, continued advances are rapidly addressing these issues, making electric haul trucks an increasingly viable and attractive option for industrial applications.

Battery technology and charging times used in electric haul trucks

electric haul trucks predominantly use advanced lithium-ion battery technology because of its high energy density, high efficiency and relatively fast charging capabilities. Here are some key aspects of battery technology and charging times for these trucks:

Battery capacity and type:

Lithium-ion batteries: these electric haul trucks batteries are favoured for their high energy density and high efficiency. For example, Caterpillar's 793 electric dump truck uses a lithium-ion battery pack capable of storing large amounts of energy, allowing the truck to operate efficiently in harsh mining environments.

Battery Management System (BMS): electric haul trucks use an advanced BMS to monitor and optimise battery performance, ensuring safety, long life and efficient energy use.

Charging infrastructure and timing:

Fast charging: Companies such as Fortescue and Liebherr have developed electric haul trucks that can charge their large battery packs (e.g. 1.4 MWh) in approximately 30 minutes. This fast charging capability is essential to minimise downtime in industrial operations.

Charging stations: Deploying a robust charging infrastructure is essential. These charging stations for electric haul trucks are often equipped with high-capacity chargers that can quickly and safely deliver the necessary power to the truck's battery system.

Energy recovery systems: Regenerative braking systems for electric haul trucks are used to recover energy during braking and then feed it back into the battery. This feature not only increases efficiency, but also reduces the frequency and duration of charging.

Innovations and future developments:

Solid-state batteries: Research and development is ongoing in the field of solid-state batteries, which promise higher energy density and faster charging times than current lithium-ion technology. These advances could further improve the performance and viability of future electric haul trucks

Hydrogen Fuel Cells: Some companies are exploring the use of hydrogen fuel cells as an alternative or supplement to battery electric systems. Hydrogen fuel cells can provide long run distances and fast refuelling times, although the hydrogen infrastructure is still under development

Overall, the battery technologies used in electric haul trucks are at the forefront of energy storage innovation and are being continually improved to increase their performance, shorten charging times and expand their operational capabilities.

environmental benefits of switching to electric haul trucks

electric haul trucks offer a number of environmental advantages over conventional diesel trucks, contributing significantly to the reduction of mining and industrial operations

electric haul trucks reduce greenhouse gas emissions:

Zero tailpipe emissions: electric haul trucks produce no tailpipe emissions, which directly reduces the amount of carbon dioxide (CO2) and other greenhouse gases emitted into the atmosphere. This is critical for industries such as mining, where emissions from heavy-duty vehicles are a major source of pollution.

Contribution to climate goals: By reducing emissions, electric haul trucks help organisations to achieve sustainability goals and align with global climate objectives. Vale, for example, aims to reduce its carbon emissions by 33 per cent by 2030 and achieve net zero emissions by 2050, in part through the use of electric haul trucks.

electric haul trucks make air quality improvements:

Elimination of particulate matter: Diesel engines emit particulate matter (PM) and nitrogen oxides (NOx), which contribute to air pollution and respiratory problems. electric haul trucks eliminate these emissions and improve air quality, especially in confined environments such as mines.

Health benefits: Better air quality improves the health of workers and neighbouring communities, reducing the incidence of respiratory diseases and other health problems associated with air pollution

Reduced noise pollution:

Quieter operation: electric motors run quieter than diesel engines, reducing noise pollution. This benefits both the workers operating the trucks and the surrounding environment, contributing to a safer and more enjoyable work atmosphere.

energy efficiency of electric haul trucks:

More efficient: electric haul trucks are more energy efficient than diesel trucks. An electric motor converts a higher percentage of battery energy into motion than a diesel engine, which loses a significant portion of its energy in the form of heat. This efficiency reduces overall energy consumption.

Regenerative braking: These trucks typically use regenerative braking, which recovers energy during braking and stores it back in the battery, further improving energy efficiency and reducing the need for frequent recharging.

electric haul trucks support renewable energy:

Integration with renewable energy: electric haul trucks can be recharged using renewable energy sources such as solar and wind, further reducing their environmental impact. Companies are investing in renewable energy infrastructure to support the operation of electric vehicles and reduce dependence on fossil fuels.

Overall, the adoption of electric haul trucks offers a significant opportunity for industries to reduce their environmental impact, improve worker health and safety, and move towards a more sustainable and environmentally friendly future.

Which companies are using electric haul trucks and how they are used in real-world applications

Leading aggregate producer CRH uses its 70 to 100 tonne battery electric off-highway mining trucks. The partnership aims to ensure that these electric trucks meet safety, performance, operational and compliance requirements, while supporting CRH's goal of net-zero greenhouse gas emissions by 2050

Major mining companies such as BHP Billiton, Freeport-McMoRan, Newmont, Rio Tinto and Teck Resources Ltd. use electric haul trucks with the goal of reducing and eliminating greenhouse gas emissions from their operations

Fortescue is integrating electric haul trucks into its mining operations as part of its commitment to sustainability. The trucks are equipped with fast charging capabilities to quickly recharge batteries and minimise downtime

Rigorous electric haul trucks testing for quality assurance

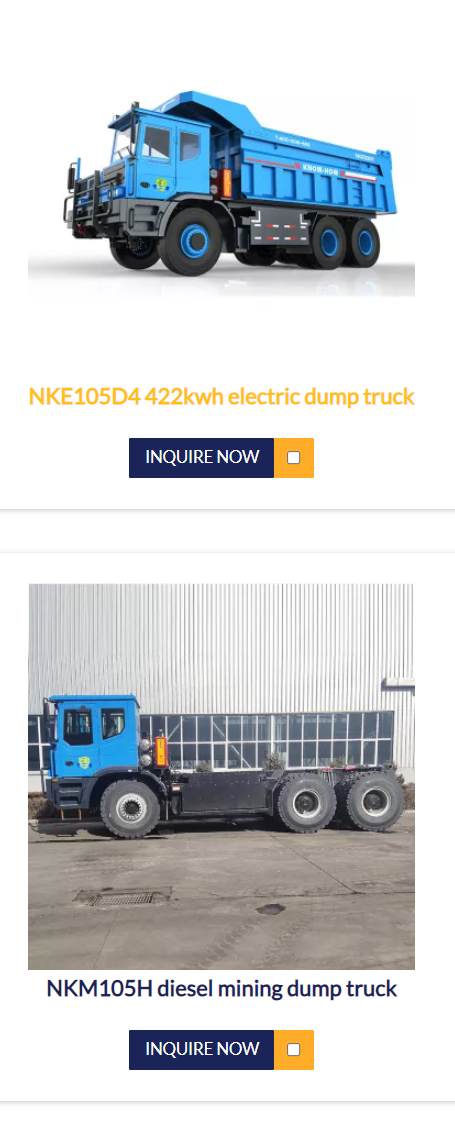

electric haul trucks manufacturer - KNOWHOW conducts rigorous electric haul trucks testing to ensure the safety, reliability and performance of electric haul trucks. Here are some of the key methods and steps used to test electric haulage trucks

Controlled environment testing: electric haul trucks are tested in controlled environments at proving grounds that simulate real-life mining conditions to evaluate the performance, safety and durability of the trucks.

Operational scenario simulation: electric haul trucks are tested in a variety of terrains and under different load conditions to simulate real mining operations. This includes steep slopes, rough terrain and long hauls to ensure the trucks can withstand the stresses of real-world use.

Extensive data monitoring: during testing, electric haul trucks are equipped with a number of sensors to collect data on performance indicators such as speed, torque, energy consumption and battery health

Performance benchmarking: The data collected is analysed to compare electric haul trucks with conventional diesel trucks and industry standards. This helps identify areas for improvement and ensures that the trucks meet safety and performance requirements

Battery safety testing: The batteries in electric haul trucks undergo rigorous testing for thermal stability, impact resistance and overall durability. This includes exposing batteries to extreme temperatures, vibration and shock to ensure they can withstand the harsh mining environment.

Charge cycle testing: the efficiency, speed and reliability of electric haul trucks' charging systems are tested. Fast charging capabilities are evaluated to ensure minimal downtime.

Real-life field trials: electric haul trucks are deployed at actual mining sites for long-term field trials. The company works with mining companies to integrate electric haul trucks into their operations, gathering feedback on performance, reliability and operational impacts.

Standards compliance: electric haul trucks are tested to ensure compliance with international safety and environmental standards. This includes testing for electromagnetic compatibility (EMC), electrical safety and compliance with emissions regulations.

Safety features: electric haul trucks are equipped with advanced safety features such as automatic emergency braking, collision avoidance systems and operator alertness monitoring. These features are rigorously tested to ensure that they function properly under all conditions