Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for mining haul truck. Your help is our eternal strength! Warmly welcome domestic and foreign customers to come to our company for business negotiation. The product will supply to all over the world, such as Bhutan ,Ecuador ,Faroe Islands ,Ghana ,New Zealand . If any products meet your needs, please feel free to contact us. With the goal of "creating first-class products", the company strives to provide customers with high-quality solutions, high-quality after-sales service and technical support, and mutual benefit with customers to create a better career and future!We welcome potential buyers to contact us. We are wanting ahead to hearing from you before long.

Trucks for Mining: Haul Trucks

What are Haul Trucks?

Mining haul trucks are large, heavy-duty vehicles specifically designed for transporting large quantities of materials within mining sites. These trucks are engineered to handle the tough conditions and rigorous demands of mining operations, making them a critical component in the extraction and transport of minerals and other materials from mines to processing facilities.

Main Components of Haul Trucks

1. Payload Capacity

Mining haul trucks are built to carry massive loads, often exceeding hundreds of tons. The payload capacity is a key factor that determines the efficiency and cost-effectiveness of mining operations. Higher payload capacities mean fewer trips and greater productivity.

2. Diesel Engine

The diesel engine is the powerhouse of a mining haul truck. These engines are specifically designed to provide the immense torque and power needed to haul heavy loads up steep inclines and across rugged terrain. They are built for durability and reliability under continuous heavy use.

3. Electric Drive System

Many modern mining haul trucks incorporate electric drive systems. These systems improve fuel efficiency and reduce emissions by using electric motors to drive the wheels, while the diesel engine generates electricity. This combination offers enhanced control and power distribution.

4. Pneumatic Tires

Pneumatic tires on mining haul trucks are designed to withstand the extreme conditions of mining environments. They provide the necessary traction and stability on uneven surfaces, while also supporting the immense weight of the loaded truck. Their design includes special compounds and tread patterns to maximize durability and performance.

5. All-Wheel Drive

All-wheel drive (AWD) systems ensure that power is distributed to all wheels, providing better traction and control on challenging terrains. This feature is essential for maintaining stability and maneuverability in the rough and variable conditions typical of mining sites.

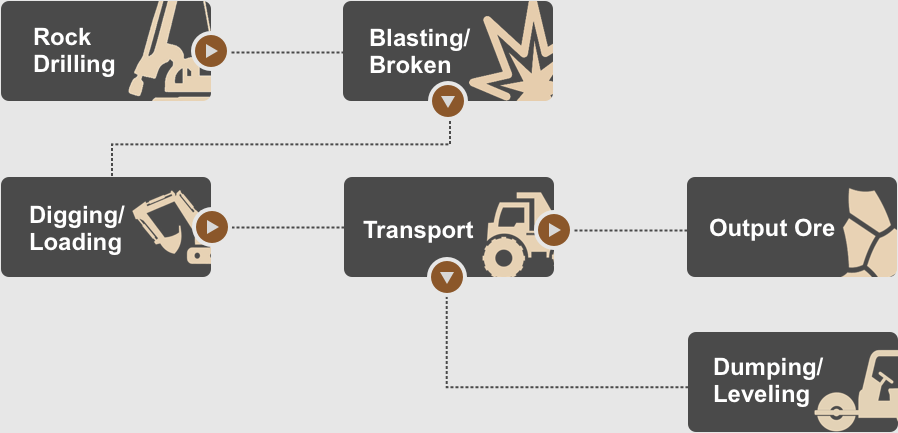

How are Haul Trucks Used in Mining?

1. Transporting Raw Materials

Mining haul trucks play a crucial role in transporting raw materials from the extraction site to processing facilities. Their ability to carry large volumes of material reduces the number of trips required, thereby increasing operational efficiency.

2. Moving Overburden

Overburden removal is a significant part of mining operations. Haul trucks are used to transport the soil and rock that lies above the mineral deposits. Efficient overburden removal is essential for accessing the valuable materials below.

3. Enhancing Efficiency

The design and capabilities of mining haul trucks directly contribute to the overall efficiency of mining operations. Their large payload capacities and robust performance reduce the time and cost associated with material transport.

4. Providing Safety for Operators

Safety is a top priority in mining operations. Haul trucks are equipped with advanced safety features, including reinforced cabins, collision avoidance systems, and automated controls, to protect operators and minimize the risk of accidents.

What Sets Haul Trucks Apart from Other Mining Trucks

1. Enormous Payload Capacities

One of the most distinctive features of mining haul trucks is their enormous payload capacity. These trucks are designed to carry significantly larger loads than other types of mining vehicles, making them essential for large-scale mining operations.

2. Size and Weight

Mining haul trucks are among the largest and heaviest vehicles in the world. Their sheer size and weight enable them to carry massive loads and endure the harsh conditions of mining sites.

3. Adaptability to Harsh Climates

Mining haul trucks are built to operate in extreme climates, from the freezing temperatures of Arctic mines to the scorching heat of desert operations. Their robust design ensures reliable performance in any environmental condition.

4. Specialized for Mining

Unlike general-purpose trucks, mining haul trucks are specifically designed for the unique demands of mining operations. Their specialized features and components are tailored to maximize productivity and safety in mining environments.

mining haul truck Case Studies

1. Successful implementations at major mines

Case studies from major mining operations around the world highlight the successful implementation of mining haul trucks. These examples demonstrate the trucks' capabilities in enhancing productivity and reducing operational costs.

2. Performance comparison between different mining sites

Comparing the performance of mining haul trucks across various sites provides insights into their adaptability and efficiency in different conditions. Such comparisons help mining companies make informed decisions about truck selection and deployment.

New vs. Used Haul Trucks

1. Cost

The cost of new haul trucks is significantly higher than used ones. However, new trucks come with the latest technology and warranties, which can reduce long-term maintenance costs.

2. Performance

New haul trucks offer the latest advancements in technology and efficiency, while used trucks may have reduced performance due to wear and tear. The choice between new and used depends on budget constraints and operational needs.

3. Maintenance

Maintenance requirements for new trucks are typically lower initially, while used trucks may require more frequent and costly repairs. Proper maintenance records can influence the decision to buy new or used.

4. Warranty

New haul trucks come with manufacturer warranties that cover major repairs and replacements. Used trucks may have expired warranties, increasing the risk of out-of-pocket expenses for repairs.

5. Availability

New haul trucks may have longer lead times due to manufacturing schedules, while used trucks are usually available for immediate deployment. This factor can be crucial in time-sensitive mining operations.

6. Resale Value

The resale value of new trucks depreciates rapidly in the first few years, while used trucks have a more stable resale value. Consideration of long-term investment returns is important when choosing between new and used trucks.

7. Environmental Considerations

Newer haul trucks often feature more efficient engines and lower emissions, aligning with environmental regulations and sustainability goals. Used trucks may not meet the latest standards, potentially leading to higher operational costs due to environmental compliance.

mining haul truck Future Trends

1. Electrification and sustainable practices

The mining industry is increasingly adopting electrification to reduce emissions and enhance sustainability. Electric haul trucks are becoming more common, driven by advancements in battery technology and environmental regulations.

2. Increasing payload capacity

Ongoing research and development aim to increase the payload capacities of haul trucks. Innovations in materials and engineering are enabling the design of trucks that can carry even larger loads, further enhancing mining efficiency.

3. Development of hybrid trucks

Hybrid haul trucks, combining diesel and electric power, offer a balance between performance and environmental impact. These trucks are gaining traction as a viable solution for reducing fuel consumption and emissions while maintaining operational efficiency.

Conclusion

Mining haul trucks are indispensable in the mining industry, providing the necessary capabilities to transport large quantities of materials efficiently and safely. Their specialized design, enormous payload capacities, and adaptability to harsh conditions set them apart from other mining vehicles. As the industry evolves, trends such as electrification and increased payload capacities will continue to shape the future of mining haul trucks, driving advancements in efficiency and sustainability.